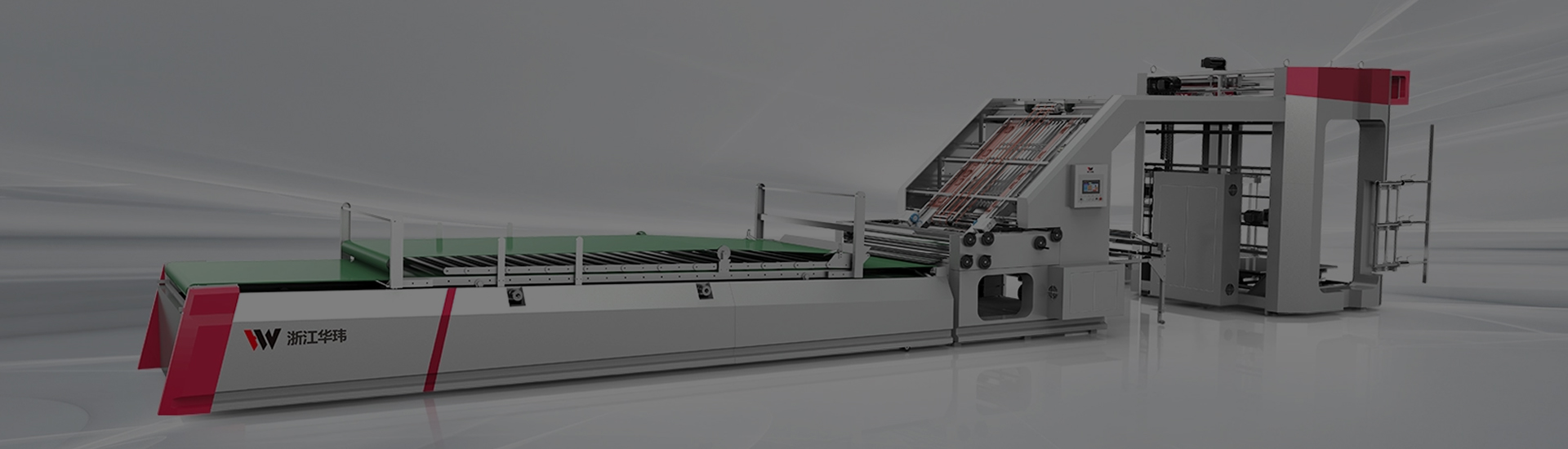

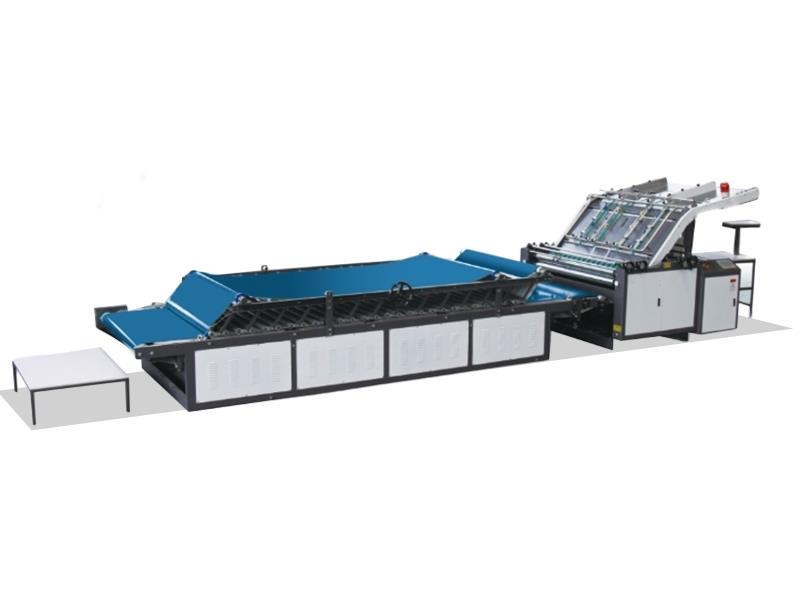

1. Top paper feeding by hand, feeding table incresed height, easy feeding and easy operation

2. Bottom corrugated sheet auto vacuum feeding, continuous automatic tracking according top paper feeding speed

3. Entire new concept,front gauge registration, position high accuracy, 1mm precision

4. The scientific design of the metering roller speed to ensure the glue evently on the same time, to avoid rejection of glue at high speed.

5. Imported electrical components, to ensure the stability of the circuit system. PLC tracking technology, automatic fault alarm;

6. Fully automatic glue supplementary system, can automatically replenish the loss of the amount of glue, and cooperated with the glue recycling

7. Independent water tank control cycle, ensure the bottom paper back dry, at the same time cleaning up roller、glue receive tank and back glue tank;

8. Single side adjustment of the roller pressure, and equipped with a dial gauge, the replacement of the bottom paper one-step-to- reach.

9. Floating removable press, to ensure that laminated paper will not be crushed, and also keep the cardboard smooth and straight; unilateral adjustment by way of adjustment worm roll lamination pressure for quick.

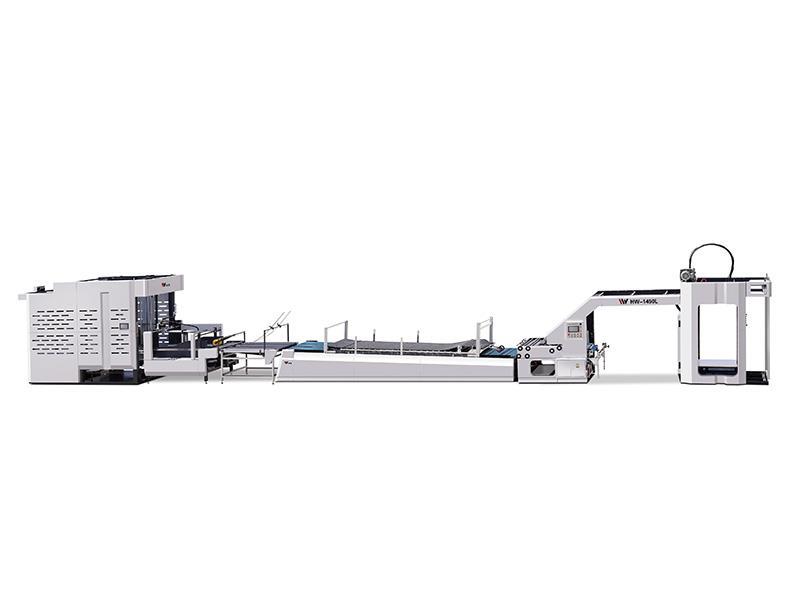

|

Model |

HW-1300H |

Hw-1600H |

|

Max size of cover face |

1300X1250mm |

1600X1250mm |

|

Mix size of cover face |

400mmX400mm |

400mmX400mm |

|

Top paper thickness |

140-800g |

140-800g |

|

Bottom sheet thickness |

2/4 ply A/B/C/E/F Flute |

2/4 ply A/B/C/E/F Flute |

|

Machine speed |

0-80m/min |

0-80m/min |

|

Precision |

±1mm |

±1mm |

|

Power |

7kw |

7kw |

|

Size |

8m x 2m x 2.9m |

8m x 2.3m x 2.9m |

|

Weight |

About 2500kg |

About 3000kg |