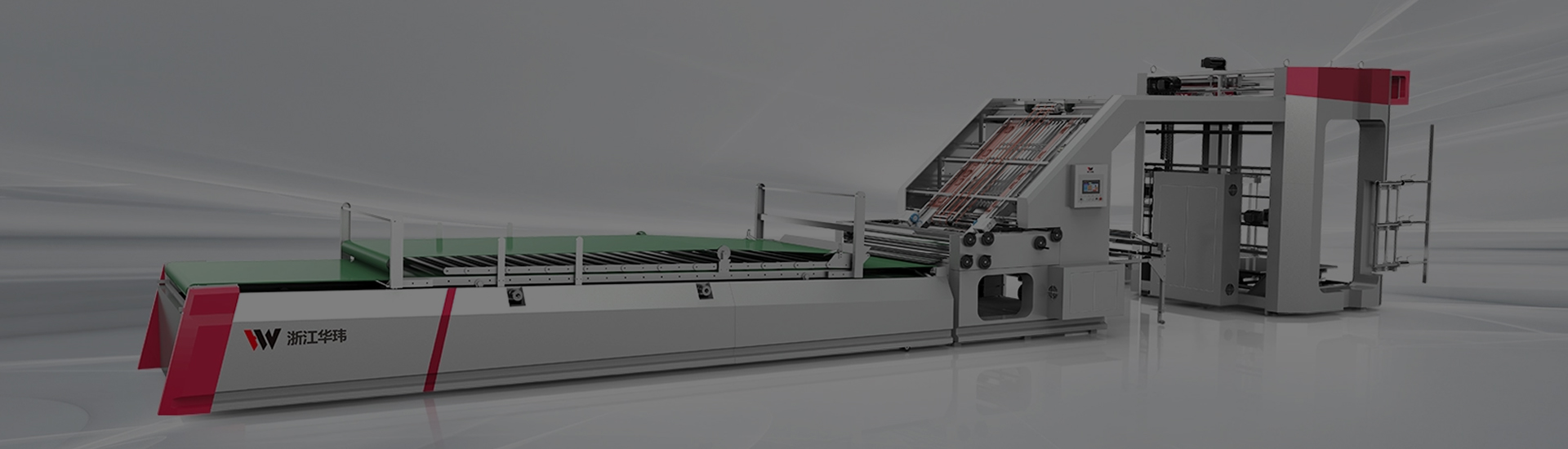

1.Appearance

The body of gantry structure, appearance of the atmosphere ,

sophisticated manufacturing.

2.Feeder

Automatic paper loading, equipped with pre-stack loading

system, loading,feeding,stripping at the same time, realize

non-stop production.

3.Stripping

Take the whole row as the unit, deal with a row of products

in one action.

The height of paper loading is increased to 10cm,significantly

improved the efficiency.

4.Manipulator

Automatic robot dispensing,controlled by the reversible gear motors,pneumatic clamp the,material,finished products to the

conveyor belt,improve transport efficiency,reduce labor costs,and improve productivity.

5.Waste Discharge Channel

The scraps of paper fall into the waste discharge channel

during the stripping process,without manual removal,

realize non-stop stripping.

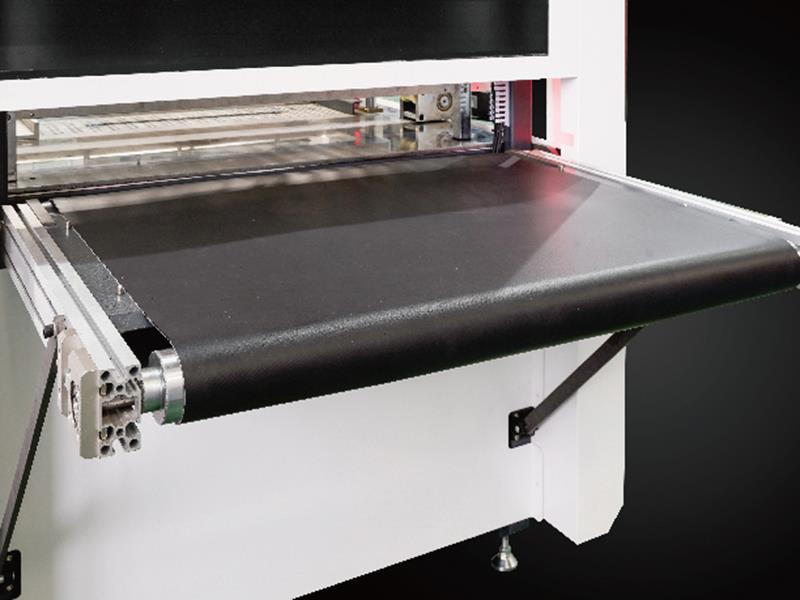

6.Paper Collecting System

Equipped with automatic paper collecting and palletizing

system, ensures neat and orderly stacking in the collection

area, making it easier to connect to the next process,

reducing labour costs and increasing production efficiency.

7.Operation System

Using servo motor driven and adopting the imported high

precision ball screw and linear guide drive to avoid the integrating

error and positioning error when machine is working;

with PLC controlling,it is convenient to operate,safe and

reliable.

1.Take the whole row as the unit, deal with a row of products in one action.

2.Realize automatic paper loading in innovative mode, which solves the long-term difficulties of waste paper stripping

equipment.

3.The scraps of paper fall into the waste discharge channel during the stripping process,without manual removal,

realize non-stop stripping.

4.The height of paper loading is increased to 10cm,significantly improved the efficiency.

5.Equipped with pre-stack loading function that can realize non-stop production.

6.Equipped with automatic paper collecting and palletizing system, ensures neat and orderly stacking in the collection

area, making it easier to connect to the next process, reducing labour costs and increasing production efficiency.

7.Using servo motor driven and adopting the imported high precision ball screw and linear guide drive to avoid the

integrating error and positioning error when machine is working; with PLC controlling,it is convenient to operate,safe

and reliable.